What is the SDCM?

Colour Matching, SDCM Or A MacAdams Ellipse

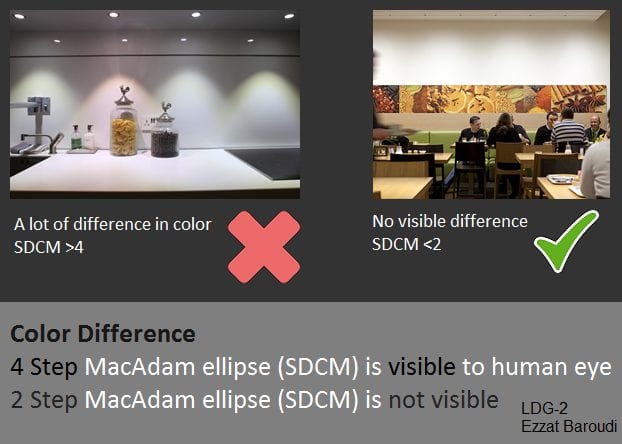

When selecting lighting, one of the key things is consistency of colour. There is little worse than seeing tubes or down lights that are all different colours.

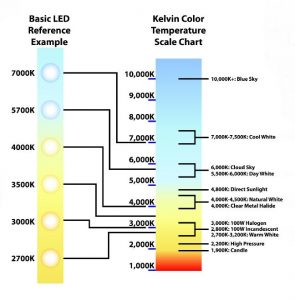

Fig 1: Kelvin Colour Temperature Scale Chart

Typically, when selecting lighting, people will choose a technology first and a colour second. The colour is normally expressed in terms of “degrees Kelvin” and looks like nnnnK Sometimes when people see this temperature, they think it is in terms of “thousands” as we are so used to expressing thousands of dollars in the following format: $10,000 = $10K, but that is not the case. Just like Celsius and Fahrenheit, Kelvin is a unit of measure for temperature.

To learn more about temperature in “Kelvin”

It is also possible to determine light colour in terms of wavelength, but that will be the subject of another article.

Assume you want a new LED light, you might order 10 at a pleasant 4000K. In a couple of weeks, you need another 5 for a different area, and when they arrive and are turned on…they just look…different. Then you realise, one is just a little more yellow than the other. But – hang on – they were both 4000K? The worst thing is that once you notice it, you can’t unsee it. It will annoy you every time you turn on the lights. What went wrong?

Colour matching of colour temperature can vary based on product type, manufacturing batch and the Standards for quality processes that the manufacturer follows. It requires attention to detail to ensure the colour is consistent within a batch and between batches.

There has been a lot of science behind understanding how colour matching with lighting can be managed.

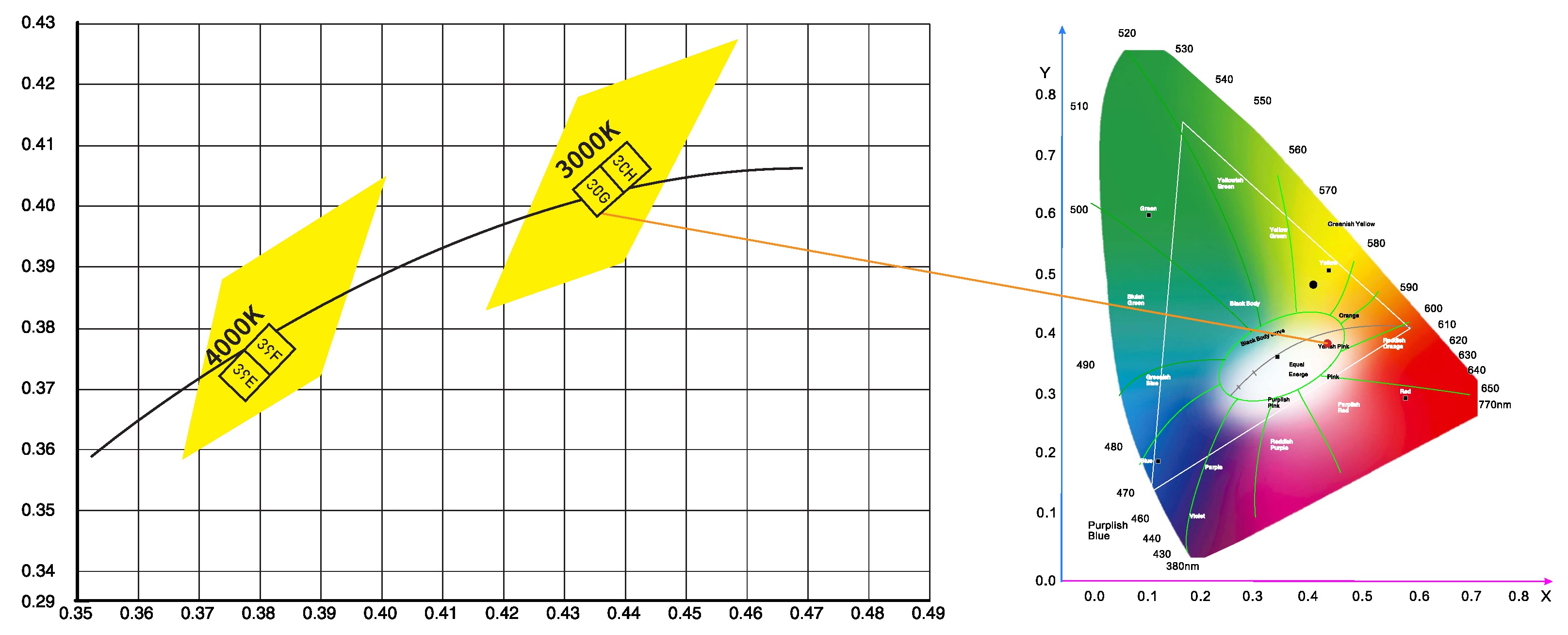

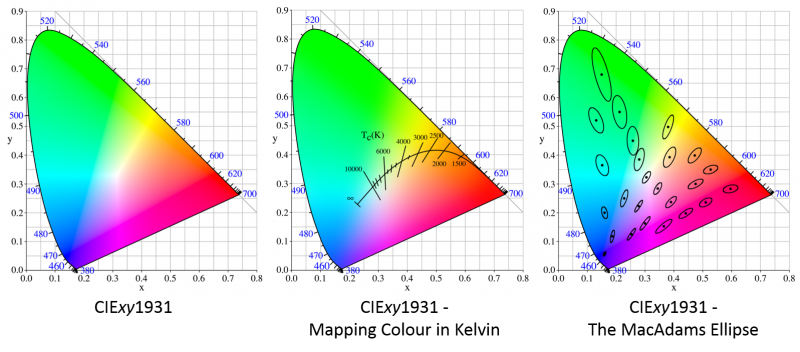

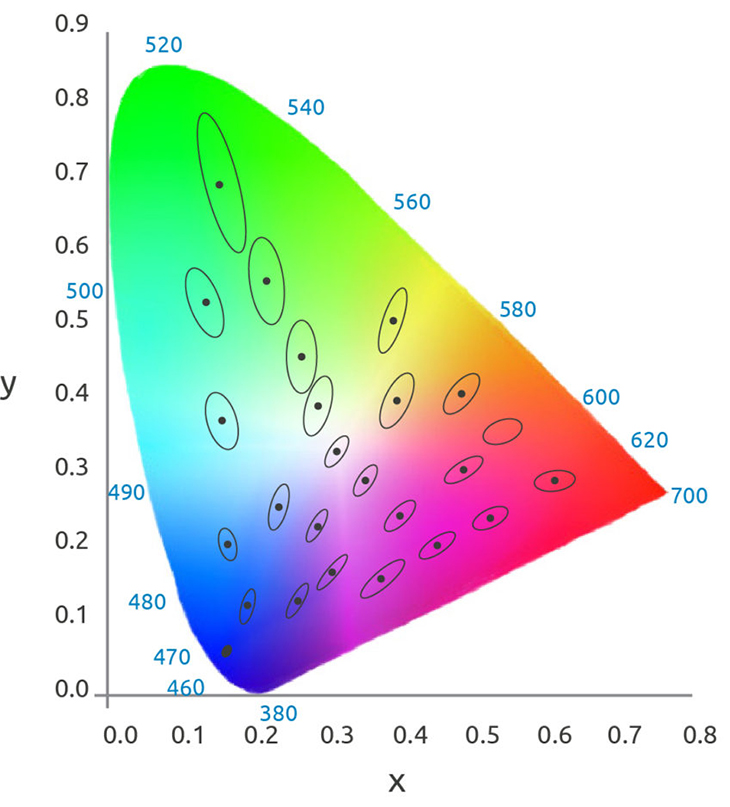

In order to minimise this issue, the International Commission on Illumination (CIE), in 1931 developed an approach to colour spaces. The CIE 1931 colour spaces diagram is still used today. In the diagrams below you can see the standard CIExy1931 diagram, how the Kelvin temperatures match to the diagram, and the last image shows how the MacAdam’s ellipses overlay the diagram.

Fig 2: CIE 1931 Chromaticity Diagram – Application in Lighting

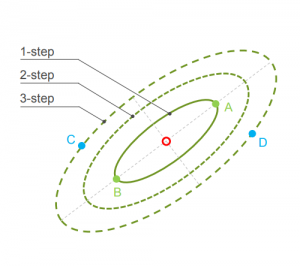

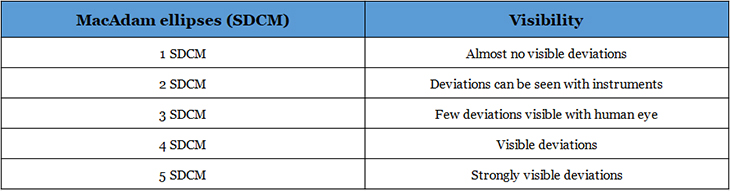

Trying to understand how this worked, Dr David MacAdam in 1942 undertook a series of experiments that focused on something he referred to as “Just Noticeable Difference” or JND. This was identified by giving the subject a fixed colour and then getting them adjust a variable colour until the colours were “the same”. Just Noticeable Difference is defined as the colour difference where 50% of observers see a difference and 50% of observers do not. Invariably, due to the natural imperfection of the human eye as a measurement device, these colours were not quite the same, however, a standard deviation of colour matching (SDCM) displayed as an ellipse around the fixed colour. If the colour falls between 1 SDCM of the fixed point, this is known as a “1-step MacAdam Ellipse”. 2 SDCM is a “2-step MacAdam Ellipse” and so on.

Fig 3: MacAdam’s Ellipse Steps

As a part of understanding the relative colour of these options, a 1-Step MacAdam’s Ellipse is the same as 1 SDCM. The lower the “Step” (or SDCM) the harder it is to perceive the difference in colours.

Dr MacAdam identified 25 fixed points around the CIExy1931 Chromaticity Diagram and he found that the shape and size of the ellipse varied significantly depending on the initial fixed colour that was selected. These fixed points and their associated ellipses are noted in Fig 2 in the rightmost image.

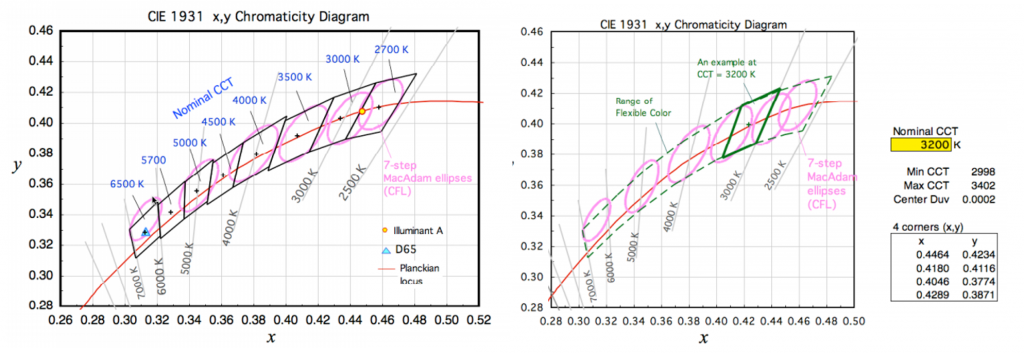

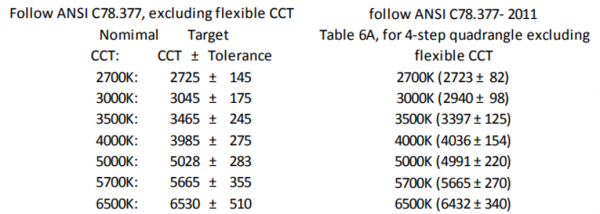

This was the basis for what is now known as the ANSI Standard C78.377-2011, which is the standard for LED lighting.

Fig 4: CCT Colour Tolerances

In the diagrams above, the ellipse and associated trapezoidal shape are clearly noted around each colour.

For a colour to be compliant, it needs to fall into a specific range, and this range is clearly noted in the standard. Fig 4 shows an example for the temperature of 3200K.

Fag 5: Colour Tolerance – ANSI C78.377-2011

If any supplier tells you they can supply at a perfect temperature, be careful. This advice is likely misleading. There will always be a range, it is just important to ensure the range is small so the variance in temperature is not perceptible.

So, the next time you are looking to purchase a new light, insist on a SDCM<4 or, even better, <3. If you can, get test results to prove the CCT of the fitting you are purchasing. If you can do that and you need to buy a second batch, you will be able to confirm the compatibility of the colour to your first batch and end up with a clean, consistent colour throughout the area being illuminated.

SDCM & MacAdam Ellipse and Why Are They Important for LED Lighting Fixtures?

In 1931 the CIE published its famous Chromaticity graph. It meant that every color that could be created by a mixture of red-green-blue could be given a unique number on the graph. Around 1940, David MacAdam ran a series of tests and demonstrated that rather than a single color is indicated by a point on a graph, it could be represented by an ellipse surrounding that point. Within the ellipse, there would be no discernible difference in color from the reference point at its center. The MacAdam ellipse shows how LEDs, belonging to a certain production line, deviate from standard values in their color consistency. And that was the birth of the MacAdam Ellipse.

MacAdam-ellipses-plotted-on-the-CIE-1931-xy-chromaticity-diagram

Until the introduction of the LED, there was very little practical use for the MacAdam ellipse. Light sources were mass-produced and color tolerances were sufficiently controlled that very few people complained about color inconsistencies between two lamps.

However, with the introduction of the LED module, the method of light production changed. The manufacturing process is such that millions of LED chips are produced from an assembly line every day and it’s inevitable that there will be color inconsistencies between individual chips and the modules built from them.

In the early days of LED production, the quality of the product was determined by the accuracy of the binning process of chips. This was the way that LEDs were separated into separate bins according to their colour output. It was an expensive and time-consuming process. Improvements in LED module design have brought the Macadam Ellipse to the forefront of the color checking process.

A perfect LED module assembly line will produce batches of modules operating within a MacAdam Ellipse. There will be no discernible difference between any of the module outputs. LED modules produced at this level are used where color performance and accuracy between fixtures is vitally important. Typically, good LED modules are produced within a two to three MacAdam ellipse range, here will be a visual difference if you look for it, but it is minor and generally considered to be acceptable in commercial usage. The following table provides an overview:

MacAdam Ellipse

Tighter control of the color of LEDs is desirable, but this must be balanced with the associated costs of doing so. The production of LEDs has improved over time, and manufacturers are able to control the resulting color output today. But there are still color variations based on certain manufacturing tolerances. Production of LEDs is sorted (binned) by proximity to the center point, resulting in varying quantities in each bin. If an LED manufacturer has good control over the various inputs, the majority of production will fall within the tighter ellipses, but there will still be LEDs that fall into the larger ellipses. Pricing of these LEDs follows the law of supply and demand, so the smaller, more desirable ellipses are more costly. High-quality products may have a higher price, but the greater consistency in color temperature and brightness make them a worthwhile investment.